Optical Image Stabilization (OIS) was originally developed for cameras, especially DSLR lenses. The factor that led to this innovation was that when photographers captured photos handheld, the images were blurry. The same issue occurs with outdoor cameras in windy environments, or when a truck passes by a camera causing vibrations.

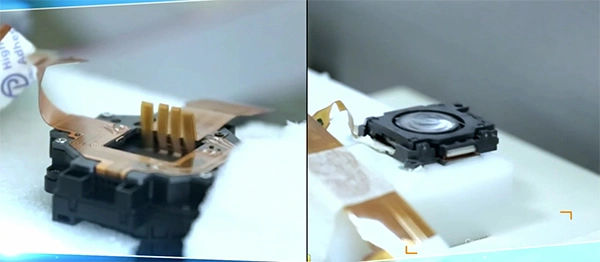

Union-Optech has focused on OIS development since 2013. The company uses high-precision gyroscopes, VCM (voice coil motors), piezoelectric ceramic drivers, and magnetic closed-loop control. This setup allows 5-axis, 50Hz high-frequency compensation with a lifespan of over 500 million cycles. We’re now at the third generation of OIS technology, reaching millimeter-level precision and constantly improving reliability and durability. Below are some pain points that OIS can already solve:

- Security surveillance: OIS solves the problem of image distortion caused by vibrations (wind, traffic), especially for long-focus lenses.

- Smartphones: OIS ensures high-quality imaging by reducing camera shake, even in low-light conditions, when shooting at long focus or close-ups. The result is a movie-grade stabilization.

- Digital cameras: OIS eliminates image blur caused by hand shake.

- Sports cameras and drones: OIS, paired with wide-angle lenses, minimizes strong shakes and turbulence, providing stable footage.

With the evolution of manufacturing techniques, OIS systems are moving from 2-axis to 3-axis and 5-axis systems. Advanced stabilization systems will find broader applications: smartphones and drones will adopt OIS even in economy models, and automotive cameras will use it for navigation, obstacle detection, and counteracting vibrations. Current systems often use VCM (voice coil motors), and the industry is moving toward piezoelectric ceramic drivers, which offer higher precision and longer durability.

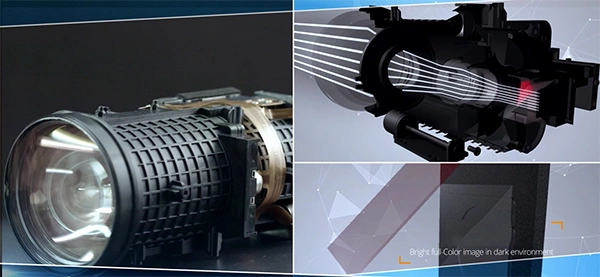

The low-light full color imaging technology fuses visible-light and near-infrared imaging into a single image. Visible-light imaging captures colors and details under normal conditions, while near-infrared imaging operates effectively in low-light environments. Built-in dual sensors capture both color and brightness information from the two light sources, and when combined, they deliver high-definition, true-to-life images even in dim settings.

The fusion of visible light imaging and near-infrared imaging lets the camera capture more information about the image. Software algorithms process the images and fuse the visual data into very clear footage. This solution is widely applied in security surveillance and traffic monitoring, where standard cameras fail to deliver high-quality imaging, especially in low-light conditions. With this technology, traffic monitoring no longer needs to rely on additional lighting, while pedestrians and drivers won’t be blinded by unexpected light flashes. Security monitoring cameras can now shoot in darkness, being invisible while delivering color, clean imagery with no compromise in quality.

Technological TrendsThe low-light full color imaging technology has already gained recognition among clients in different industries, enabling consistent true-color imaging. It is expected to move forward toward integration into smart industrial systems, machine vision, and autonomous driving.

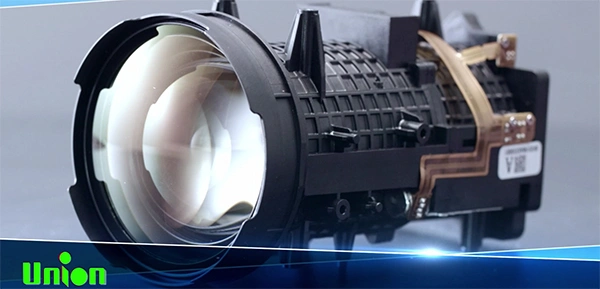

Fast focus technology enables the lens to quickly adjust focus, while ensuring sharpness and accuracy of the footage. At the core is the concept of magnetic levitation motors that use magnetic forces to move lenses. At the same time, high-precision closed-loop feedback and control algorithms are used to ensure smooth and fast focusing.

Over four years, our R&D team developed and optimized the solution from the initial concept to full application. We’ve faced and overcome such difficulties as magnetic leakage, coil overheating, and instability under extreme temperatures. The result is a reliable and effective fast focus technology for security surveillance and industrial automation fields.

As fast focus greatly boosts the effectiveness of monitoring and automation systems, it’s in great demand in video monitoring, machine vision, autonomous driving, and military surveillance, where real-time responsiveness and high precision are critical. Compared to traditional lenses, which may take 4-5 seconds to switch between wide and narrow fields of view, fast focus lenses perform this task in 0.2 seconds. This overcomes the challenge of capturing targets in busy areas like crossroads, subway entrances, malls, or residential estates. Machine vision also integrates optical technologies to enable precise and reliable quality inspection, robotic vision, and defect and feature identification.

Technological TrendsInitially, utilized in security and surveillance systems, fast focus technology is now entering industrial automation, robotics, and smart driver-assistance systems. It has been integrated into machine vision, quality inspection, and autonomous decision-making and continues to pave the way for a broader list of applications.

Stock code

Stock code