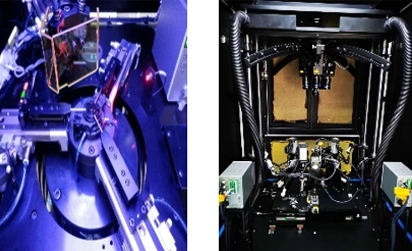

Union-Optech has comprehensive in-house development and production capabilities to ensure that every step from optical design and mold development to automated manufacturing is handled with high-level proficiency and technical precision. The company can produce up to 60 sets of optical lens molds and 100 sets of precision component molds per month, and has comprehensive expertise in designing and manufacturing both glass and plastic aspherical lenses. Its facilities include a large number of advanced machines, such as nano-level aspherical precision lathes, ultra-precision machining centers, and high-precision wire cutting EDM machines.

Union-Optech has 61 production lines and 2,500 employees, including 25 automated high-precision lines. Its monthly output reaches 10 million fixed-focus lenses and 2 million zoom lenses. With advanced equipment and mature manufacturing processes, Union-Optech ensures high product quality, stable supply capacity, and reliable optical solutions for customers worldwide.

| Machine List | Quantity |

| Nano-Level Aspherical Precision Lathe | 10 |

| Ultra-Precision High-Speed Machining Center | 7 |

| Precision Wire EDM Machine | 5 |

| Precision Mirror EDM (Electrical Discharge Machine) | 6 |

| Precision Grinding Machine | 8 |

| Precision Internal/External Cylindrical Grinder | 2 |

| Precision CNC Lathe | 2 |

| General Machining Equipment (Turning, Milling, Grinding) | 20 |

| Coordinate Grinding Machine | 1 |

| Nano Machining Center | 1 |

| Lens Equipment Processing Capability | |||

| Material | Standard | Equipment Capacity | Design & Processing Requirements |

| Lens | Decentering | 0.3-0.5μ | 0.5-1μ |

| Surface Shape | 0.003μ | 0.03μ | |

| Black Coating | Tolerance & Precision | 1μ | 3-5μ |

5-Axis Precision Machining Center

Precision Wire Cutting EDM Machine

Coordinate Grinding Machine

Ultra-Precision Diamond Turning Lathe

Precision Electrical Discharge Machining (EDM)

Precision CNC Lathe

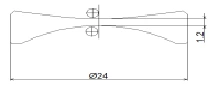

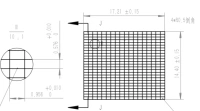

| Type | Ø 50 mm Plano-Convex | Ø 33.2 mm Double-Convex | Ø 33.7 mm Meniscus | Ø 25.8 mm Meniscus with High Thickness-to-Diameter Ratio | Ø 24 mm Double-Concave | Glass Compound Eye |

| Example |  |  |  |  |  |  |

|  |  |  |  |  |

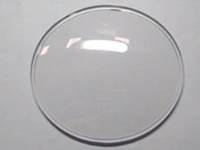

Aspherical Lens

Aspherical Lens

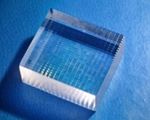

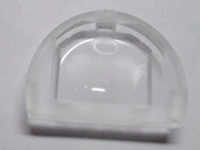

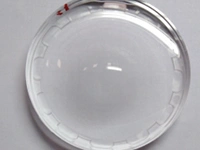

Fresnel Lens

Fresnel Lens

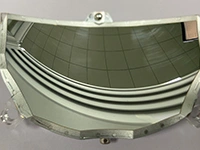

Reflective Mirror

Reflective Mirror

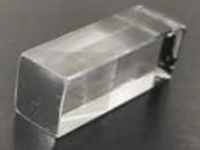

Prism

Prism

Ø 76.5mm

Ø 76.5mm

Ø 67.8mm

Ø 67.8mm

Ø 60.0mm

Ø 60.0mm

Ø 53.8mm

Ø 53.8mm

Ø 49.0mm

Ø 49.0mm

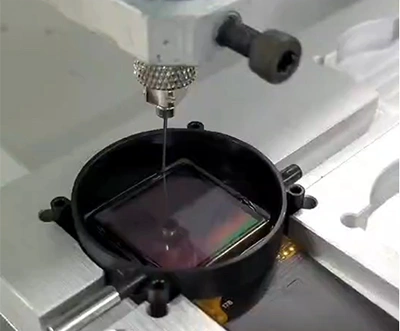

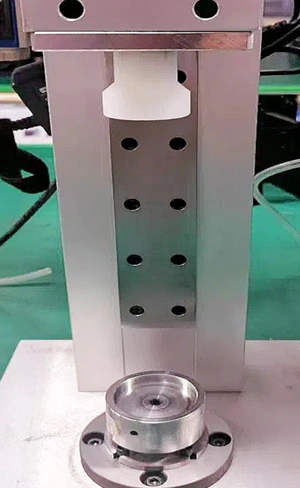

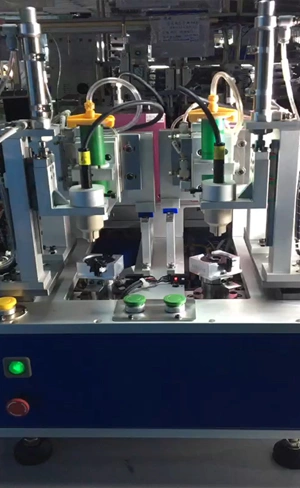

Union-Optech has developed an automated lens-to-barrel assembly process that ensures consistent optical quality and significantly enhances production efficiency.

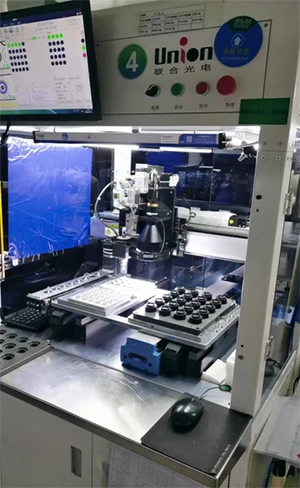

The company has also established an industry-leading, standardized demonstration line that sets a benchmark for precision optical manufacturing.

Discuss your project needs with our engineers and explore how Union Optech can provide tailored optical solutions with proven precision and reliability.