Being a technological leader in the optoelectronics industry, Union-Optech has comprehensive in-house development and production capabilities to ensure that every step from optical design and mold development to automated manufacturing is handled with high-level proficiency and technical precision. The company developed the world’s first full color imaging technology for low-light environments. With breakthrough innovations in fields such as optical image stabilization, aspheric/freeform optics, and optical waveguides, combined with nano-level precision processing capabilities, the company continues to raise the bar in industry standards. Global recognition of the company’s processes is backed by ISO 9001/14001/45001, GB/T 29490 international certifications.

The company’s R&D expertise spans over a range of advanced technologies, such as low-light full color imaging technology, optical image stabilization (OIS), fast focus and zoom technologies, infrared confocal imaging technology, ultra-short focus technology, P-IRIS precision aperture control, freeform optics, anti-vibration simulation, ultra-low reflection technology, and finite element simulation.

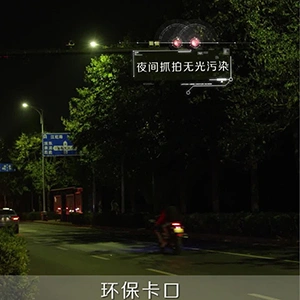

The low-light full color imaging technology fuses visible-light and near-infrared imaging into a single image. Visible-light imaging captures colors and details under normal conditions, while near-infrared imaging operates effectively in low-light environments. Built-in dual sensors capture both color and brightness information from the two light sources, and when combined, they deliver high-definition, true-to-life images even in dim settings.

Low-light mode off

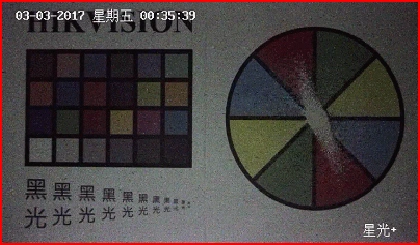

Low-light mode off

Even a starlight camera can’t deliver completely smooth, noise-free images.

Low-light mode on

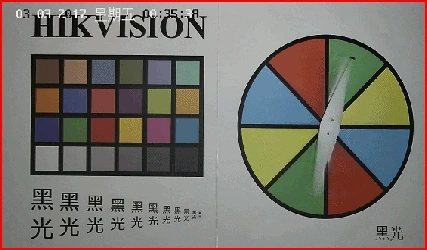

Low-light mode on

With Union-Optech’s full color imaging solution, images remain clear, sharp, and vivid even under low light.

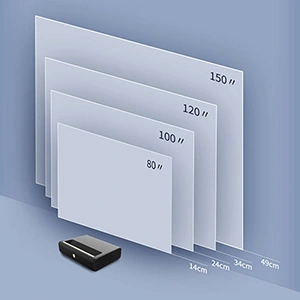

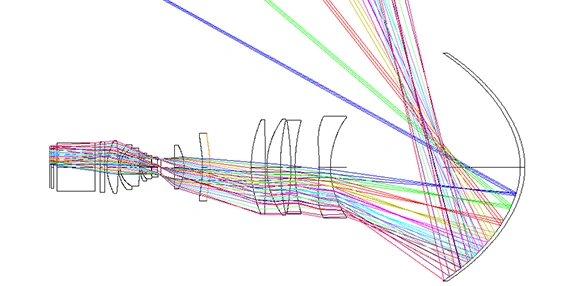

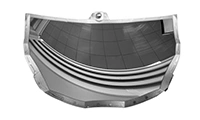

Union-Optech developed an ultra-short throw lens, which can project a large image from a very short distance. This solution is a real lifesaver for those who have limited space, but require professional quality visuals. It is widely used in home cinemas, classrooms, and business meetings.

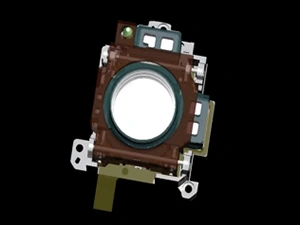

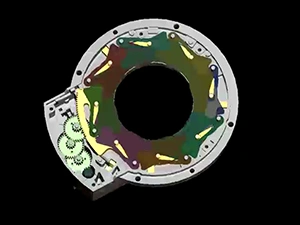

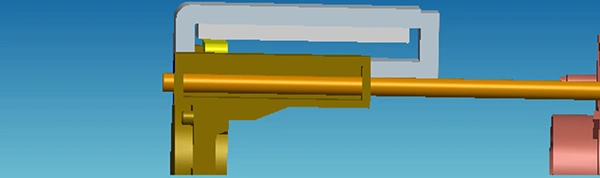

At the core of the technology are electromagnetic mechanisms and highly reliable structural design, which allows precise control of micro-movements. OIS ensures high-quality imaging by reducing camera shake, even in low-light conditions, when shooting at long focus or close-ups. This is the first industrial-grade product to combine optical stabilization with automatic aperture control.

Lens O.I.S

Lens O.I.S

Reliability: 700 million cycles

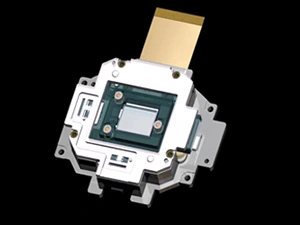

Sensor O.I.S

Sensor O.I.S

Reliability: 500 million cycles

OIS on

OIS on

OIS off

OIS off

Precisely controls the lens opening for sharper, clearer images in any light. This technology is widely used in professional cameras, industrial imaging systems, and security applications where high image quality and reliability are essential.

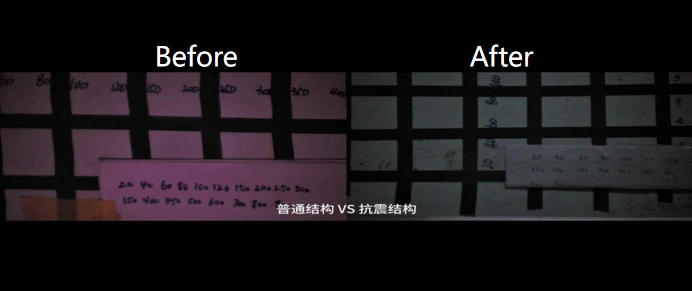

| Order | Frequency/Hz | Mode description | |

| Before adjustment | After adjustment | ||

| 1 | 474.7 | 1585 | Front group torsion |

| 2 | 513.1 | 1920.6 | Middle group torsion |

| 3 | 536.5 | 1979.3 | Middle group torsion |

| 4 | 550 | 2353.4 | Rear group torsion |

Mode 1

Mode 1

Mode 2

Mode 2 Mode 3

Mode 3 Mode 4

Mode 4

Drones: Effectively suppresses high-frequency vibrations generated by propellers during flight.

High-speed rail tracks: Enhances vibration resistance for greater stability.

Bridge monitoring: Provides significant improvements in monitoring accuracy and reliability.

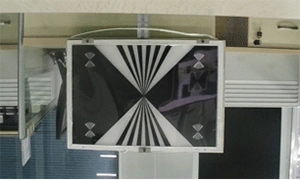

Infrared confocal imaging technology keeps images clear when switching between visible and infrared light. It reduces the need for refocusing and works well in mixed or low-light conditions.

White light mode

White light mode

Infrared light mode

Infrared light mode

In white light mode, the lens is focused for a clear image. When switched to infrared mode, the image stays almost the same in clarity.

Advantages

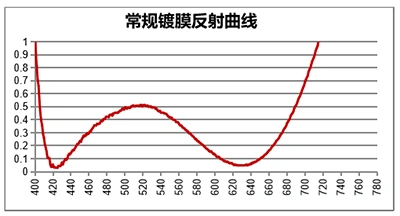

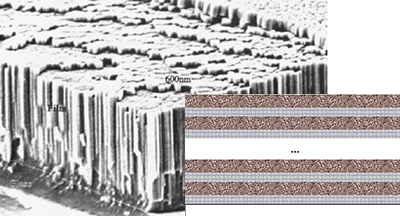

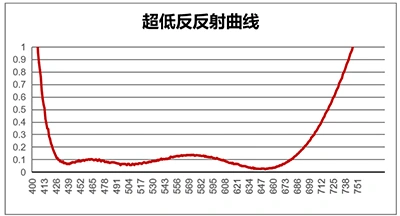

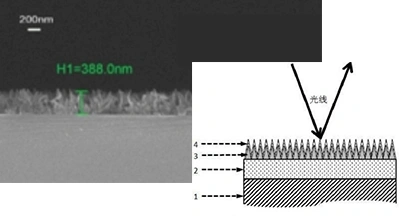

Based on multi-layer light interference, and enhanced by vacuum evaporation coating and ion-assisted deposition, this technology achieves an ultra-low reflectance of less than 0.2% in the visible spectrum (400–700 nm). It improves image quality by greatly reducing ghosting and stray light in optical systems.

Conventional coated pillar structure with slightly higher surface reflectance

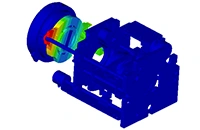

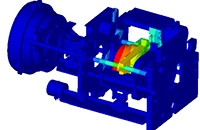

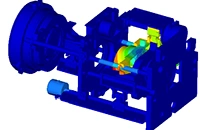

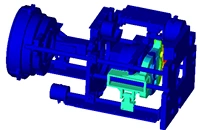

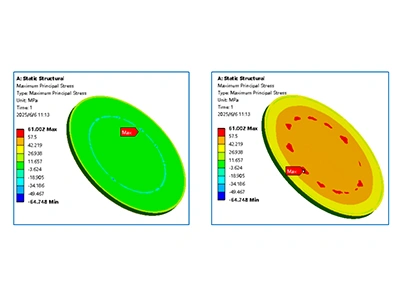

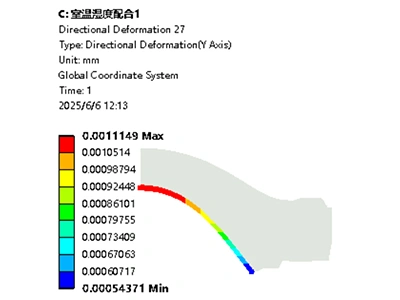

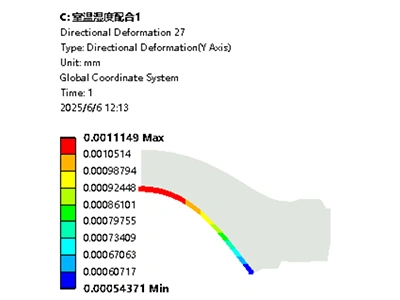

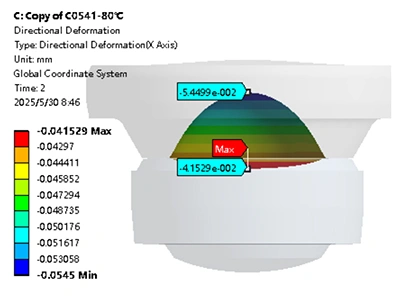

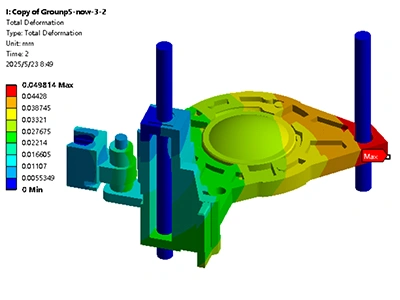

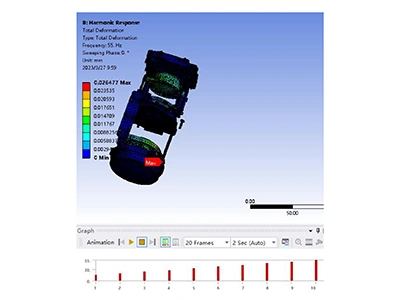

Finite element simulation allows parts, components, and complete optical systems to be analyzed under various conditions, such as static equilibrium, thermal stability, vibration, drop impact, and electromagnetic environments. It supports a wide range of design and testing needs throughout the product’s lifecycle, including strength verification, stress and deformation analysis, and electromagnetic performance assessments.

Stress analysis

Stress analysis

Stress analysis

Stress analysis Surface deformation analysis

Surface deformation analysis High/low temperature air gap analysis

High/low temperature air gap analysis Thermal expansion deformation analysis

Thermal expansion deformation analysis Lens vibration response analysis at specific frequencies

Lens vibration response analysis at specific frequenciesDiscuss your project needs with our engineers and explore how Union Optech can provide tailored optical solutions with proven precision and reliability.